Heat Transfer Vinyl Tips & Best Practices

|

Your Garment: FABRICS: Before choosing your HTV, determine what garment you will be using first. Pre-press the garment. This will remove creases and wrinkles, remove moisture and provide an even surface for pressing. Before pressing use a plain piece of parchment or a teflon sheet to avoid marking the garment. However, if you are using a synthetic fabric such as nylon or poly, pre-pressing may harm and is not necessary. Vinyl Cutter: Popular commercial-grade cutters will come in 15", 20", 24" and so on. The Roland brand is a reliable and recommended choice for professionals both small and large. Most vinyl cutters will come with their own software. Weeding Vinyl: The carrier sheet is tacky, therefore, if a piece of your design comes off, you can place it back on. You will be left with your mirrored design on the clear carrier sheet, ready for pressing! Heat Press Temperature: Allow your press to heat up to the correct temperature before using. If your heat press does not have a reliable temperature gauge, invest in an add-on temperature control unit such as the Geo Knight Digital Pyrometer & Surface Probe Kit. This unit is universal and will work with most machine brands. It's also recommended that you check your press for cold spots once a year using a laser temperature gun. |

|

How To - Step By Step:

HTV Accessory Checklist:

Your favourite HTV |

|||||

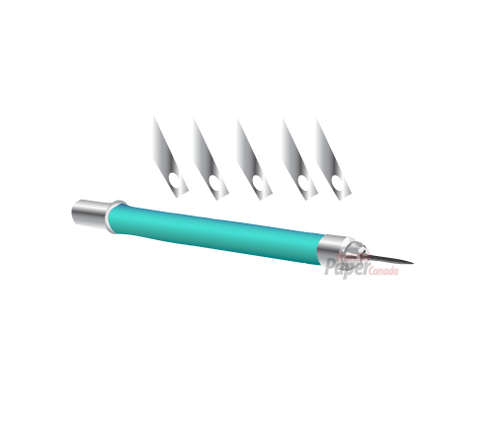

Replacement Blades |

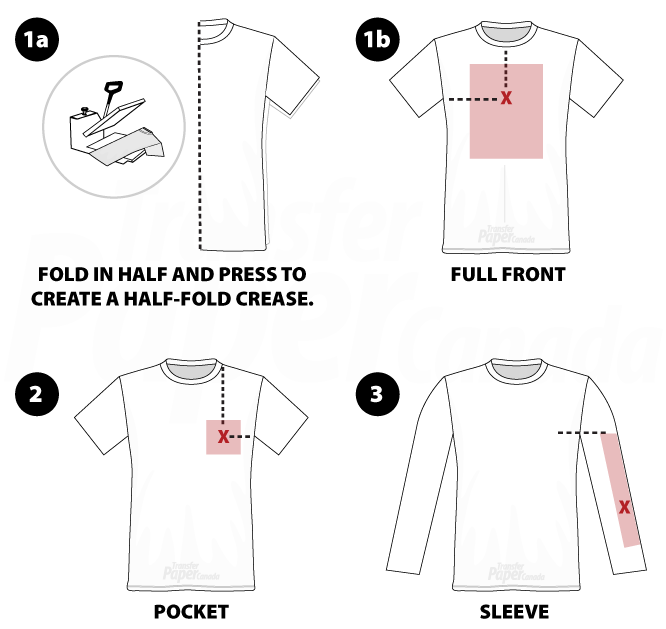

Transfer Placement & Alignment Tips:

There are many tools to help with transfer placement, but one simple way is to apply a straight transfer is to fold the garment and press so that you have a center. Then, fold the carrier sheet of your transfer in half and line up both creases. Make sure that the transfer image has the same amount of paper on either side to ensure the transfer will in fact be center of the shirt. Remember to mirror your image where required by the product.

Trouble-Shooting Checklist:

CUTTING - Which side is up? The clear, shiny side is the carrier sheet. You do not want to cut this. Place shiny side down (vinyl facing up).

CUTTING - Didn't Cut all the way through vinyl: 1). Your blade is dull, chipped or dirty. 2). Your pressure settings are not set deep enough.

CUTTING - Cut through carrier sheet: Your pressure settings are set too deep.

PROTECTION - I don't have a teflon sheet: Use a piece of parchment paper.

HEAT PRESS: HTV keeps lifting off after peel: 1). Peeling it off before it has cooled (if cold-peel). 2). It didn't have enough heat, time or pressure. 3). Pressed too long and vinyl lost its adhesion. 4). Fabric used isn't compatible with HTV.

HEAT PRESS - Which side is up? The clear, shiny side is the carrier sheet. Place facing up on your garment for pressing (dull side facing down, touching your shirt).

HEAT PRESS - HTV is wrinkled or cracking after pressing: Too much heat, for too long.

HEAT PRESS - Scorching or melting: Synthetic fabrics are heat sensitive and can scorch, burn, melt with too much heat. Be sure to check your HTV instructions for correct heat press settings, time and compatible fabrics. Using a telfon sheet may help.

WASHING - HTV peels off in washing: 1). Didn't adhere properly in heat press process. 2). Detergent used is too abrasive or harsh. 3). Wash in cold/cool cycle, inside-out. Avoid dryer.